In today’s competitive manufacturing environment, automation is no longer optional—it’s essential. One of the most impactful advancements in this arena is the integration of production robots for CNC (Computer Numerical Control) machines. These robotic systems are transforming the way manufacturers handle repetitive, time-consuming, and labor-intensive tasks, enabling lights-out production and higher output with consistent precision.

1. Introduction

In the fast-paced and quality-driven world of modern manufacturing, staying competitive requires not only precision and consistency but also automation. One of the most groundbreaking advancements in this evolution is the rise of the production robot for CNC applications. As a fusion of mechanical engineering and computer science, these robotic systems are redefining production floors globally, facilitating lights-out manufacturing, minimizing errors, and optimizing efficiency at scale.

2. What Are Production Robots for CNC?

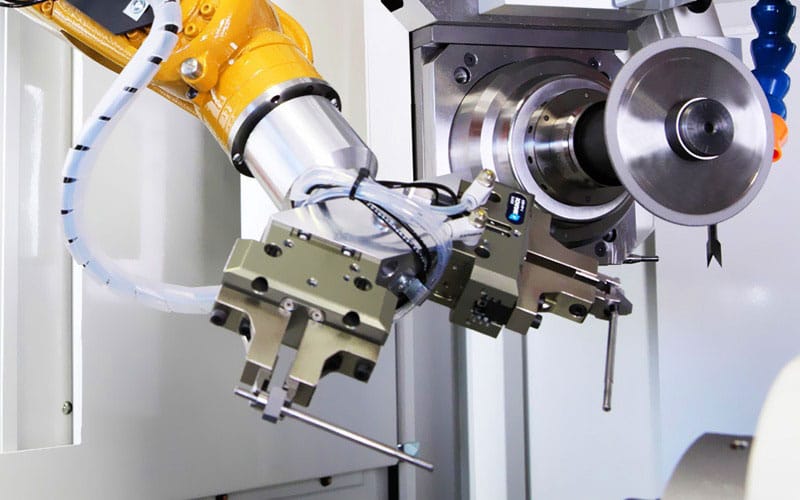

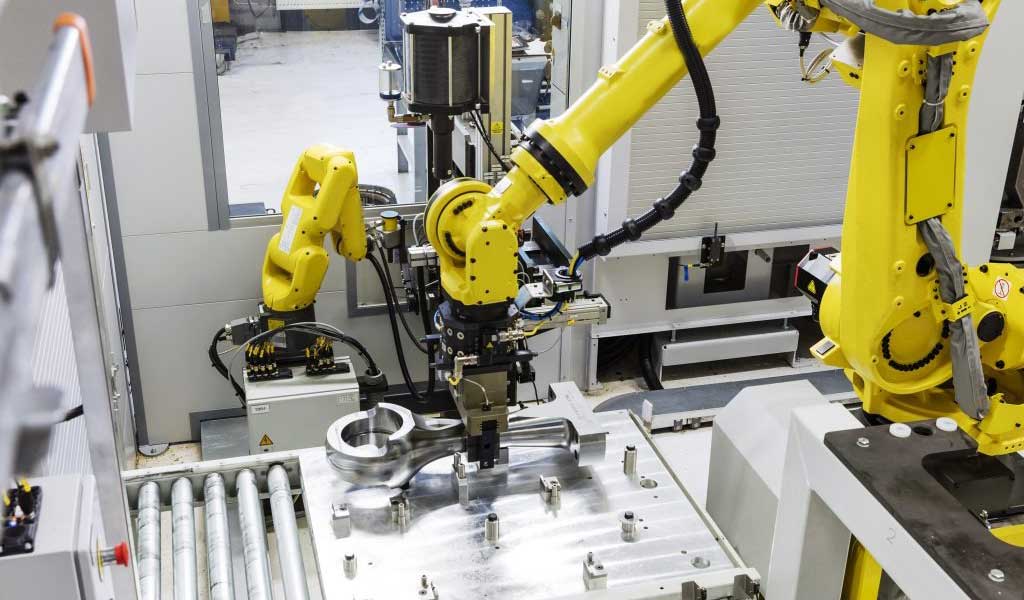

A production robot for CNC is an industrial robotic system designed to work alongside CNC machines to automate repetitive and labor-intensive tasks. These tasks include material loading and unloading, tool changing, part flipping, deburring, and quality inspection. By automating such steps, manufacturers can increase uptime, reduce costs, and enhance product quality.

Production robots can vary from six-axis articulated arms to SCARA and delta robots, depending on the complexity and precision needed. They can operate continuously with minimal human supervision, contributing directly to increased throughput and reduced operational fatigue.

3. Historical Context: From Manual to Robotic CNC Operation

Traditionally, CNC machines relied heavily on human operators for part handling, adjustments, and supervision. This manual dependency often led to downtime, inconsistency in parts, and labor fatigue. As demand for mass production, customization, and accuracy grew, the limitations of manual operations became clear.

The transition began with simple automation—like automatic tool changers—eventually evolving into fully automated cells driven by production robots for CNC. Today, many factories deploy robots not only to handle repetitive tasks but also to monitor quality and adapt in real-time based on AI-driven analytics.

4. Core Components of CNC Production Robot Systems

To function effectively, a production robot for CNC must integrate seamlessly with both hardware and software systems. Key components include:

- Industrial Robot Arm: Handles movement and manipulation of parts or tools.

- End-of-Arm Tooling (EOAT): Custom grippers, suction cups, or magnetic heads for handling specific parts.

- Vision Systems: Cameras and sensors for orientation, quality checks, and alignment.

- CNC Interface Software: Ensures data exchange between the CNC controller and the robot.

- Safety System: Includes physical barriers, light curtains, and emergency stops.

- PLC or PC-based Control Unit: Central control for task execution and communication.

5. Key Benefits of Using Production Robots for CNC

Using a production robot for CNC delivers numerous advantages:

a. Increased Uptime

Robots can operate continuously, reducing machine idle time and increasing productive hours.

b. Labor Optimization

Skilled workers can focus on programming, maintenance, and quality control rather than repetitive tasks.

c. Enhanced Accuracy and Repeatability

Unlike humans, robots don’t suffer from fatigue. Each cycle is executed with the same level of precision.

d. Cost Savings

Although initial investment may seem high, the long-term ROI justifies the cost through reduced labor and higher output.

e. Space Efficiency

Robots can be compact, operating in tight spaces and integrating into modular CNC cells.

6. Industries Benefiting from CNC Production Robots

The implementation of production robots for CNC is widespread across various sectors:

- Automotive: Mass production of engine parts, transmissions, and chassis components.

- Aerospace: Precision machining of lightweight metals and composites.

- Medical: Manufacturing surgical instruments and implants.

- Consumer Electronics: Producing small, intricate components with tight tolerances.

- Industrial Equipment: Heavy-duty part fabrication requiring consistent machining.

7. Common Applications in CNC Automation

- Automated Part Loading/Unloading

- Tool Change Automation

- Secondary Operations (Deburring, Polishing)

- In-Line Inspection and Measurement

- Palletizing and Sorting

- Inter-machine Transfer and Conveying

8. Collaborative Robots (Cobots) vs. Traditional CNC Robots

Traditional industrial robots are typically large, fast, and isolated in safety cages. Cobots, on the other hand, are designed to work safely alongside humans without barriers. When it comes to CNC applications:

- Cobots: Ideal for small shops or low-volume/high-mix production. Easy to program.

- Traditional Robots: Preferred for high-speed, heavy-load, or high-volume tasks.

Choosing between the two depends on application complexity, workspace layout, and production volume.

9. Integration Strategies and Considerations

Successfully integrating a production robot for CNC requires:

- Interface Compatibility: CNC controllers (e.g., FANUC, Siemens, Haas) must communicate smoothly with robot systems.

- Calibration and Teach Points: An Accurate setup ensures the robot interacts correctly with the CNC.

- Cycle Time Analysis: Robot operations must match or complement CNC cycle times.

- Maintenance Planning: Preventive maintenance schedules must include both CNC and robot systems.

10. Software and Communication Interfaces

Modern production environments utilize:

- OPC UA/MTConnect: Protocols for machine-to-machine communication.

- Robot Simulation Software: Helps optimize cell layout before physical deployment.

- CAM Integration: Some systems allow syncing tool paths directly with robot commands.

11. Safety and Regulatory Compliance

When deploying a production robot for CNC, safety cannot be compromised. Compliance with international standards like:

- ISO 10218 – Safety standards for industrial robots

- ISO/TS 15066 – Guidelines for collaborative robot safety

- ANSI/RIA R15.06 – U.S. safety standard for robot systems

It is essential for protecting workers and avoiding liability.

12. Economic Impact and ROI Analysis

A well-integrated production robot for CNC can pay for itself within 1–3 years. ROI is influenced by:

- Labor cost savings

- Increased throughput

- Reduction in part rework and scrap

- Longer machine lifespan due to consistent handling

Many manufacturers also report improved customer satisfaction due to faster lead times and higher-quality parts.

13. Future Trends in CNC Robotics

- AI-Powered Adaptive Robots: Learning and optimizing in real-time.

- Digital Twins: Simulating CNC cells before deployment.

- Mobile Robots + CNC: AMRs feeding CNCs across the factory.

- Cloud Integration: Centralized data collection and monitoring.

- Edge Computing: On-device analytics for speed and autonomy.

14. Case Studies and Real-World Examples

Case 1: Automotive Manufacturer in Germany

Implemented six-axis robots for CNC lathe tending. Result: 30% reduction in cycle time and ROI in 18 months.

Case 2: U.S. Aerospace Supplier

Deployed cobots to assist with 5-axis CNC machines. Result: Increased flexibility and reduced fixture cost.

Case 3: Asian Electronics OEM

Integrated vision-guided robots to sort CNC-milled casings. Result: Zero errors and fully unmanned night shifts.

15. Challenges and Limitations

While promising, integrating production robots for CNC can be challenging:

- High upfront cost

- Need for specialized talent

- Complex programming for high-mix jobs

- Downtime during initial setup or maintenance

- Limited ROI for extremely low-volume operations

16. How to Choose the Right Production Robot for CNC

Consider:

- Payload and reach

- Speed and acceleration

- Integration flexibility

- Support and documentation

- Vendor track record in your industry

17. Vendor Evaluation Checklist

CriteriaDescription

Compatibility Works with your CNC controller brand

Customization, Tailored EOAT, and software options

Support Local technical support and training

Safety ISO-compliant and reliable fail-safes

Case Studies: Proven record in CNC environments

18. Conclusion

The integration of production robots for CNC machining is no longer a luxury—it’s a competitive necessity. As global markets demand higher productivity, lower costs, and greater agility, robotic CNC automation offers an unparalleled edge.

By leveraging the power of robotics, manufacturers not only increase efficiency but also future-proof their operations. Whether you’re a small machine shop or a large-scale OEM, adopting production robots for CNC could be the smartest step toward intelligent manufacturing.