Introduction

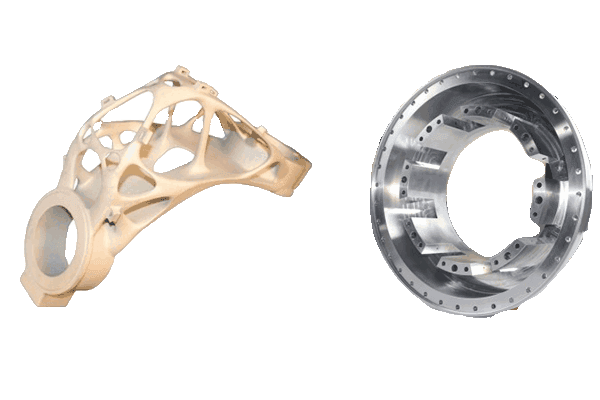

In today’s rapidly evolving manufacturing industry, two technologies have gained significant attention for their ability to produce precise, functional metal parts: Metal 3D Printing and CNC Machining. These methods represent two distinct approaches to creating components — one builds parts layer by layer from digital designs, while the other removes material from a solid block using computer-controlled tools.

Choosing between Metal 3D Printing vs. CNC Machining requires understanding their differences in process, capabilities, cost, and suitable applications. Both are powerful manufacturing solutions, yet they excel in different contexts. This article provides a comprehensive comparison to help engineers, designers, and manufacturers make informed decisions.

What is Metal 3D Printing?

Definition and Principles

Metal 3D printing, also known as metal additive manufacturing, is a process in which metal parts are created layer by layer directly from a digital 3D model. This process eliminates the need for molds, dies, or extensive tooling, enabling complex geometries that are difficult or impossible to achieve through traditional methods.

The principle is simple yet powerful: a digital CAD model is sliced into thin layers, and a machine deposits or fuses metal material layer by layer until the final part is formed.

Common Metal 3D Printing Technologies

- Selective Laser Melting (SLM)

- Uses a high-powered laser to fully melt metal powder particles layer by layer, resulting in fully dense metal parts.

- Direct Metal Laser Sintering (DMLS)

- Similar to SLM but involves sintering metal powder instead of fully melting it, allowing for slightly different material characteristics.

- Binder Jetting

- Deposits a liquid binding agent onto layers of metal powder, followed by sintering in a furnace to achieve final strength.

- Electron Beam Melting (EBM)

- Uses an electron beam in a vacuum environment to melt metal powder, often used in aerospace and medical implants.

Suitable Materials

Metal 3D printing supports a variety of materials, including:

- Stainless steel

- Titanium alloys

- Aluminum alloys

- Inconel and other superalloys

- Tool steels

What is CNC Machining?

Definition and Principles

CNC machining (Computer Numerical Control machining) is a subtractive manufacturing process where computer-controlled tools remove material from a solid workpiece to achieve the desired shape. Unlike additive manufacturing, CNC machining starts with a larger piece of material and carves away excess.

Common CNC Machining Processes

- Milling – Uses rotating cutting tools to remove material.

- Turning – Rotates the workpiece against a cutting tool for cylindrical parts.

- Drilling – Creates precise holes in the material.

- Electrical Discharge Machining (EDM) – Uses electrical sparks to erode material for intricate shapes.

Suitable Materials

CNC machining works with:

- Metals (aluminum, steel, titanium, brass, copper, etc.)

- Plastics

- Composites

Metal 3D Printing vs. CNC Machining: Core Differences

1. Manufacturing Process

- Metal 3D Printing builds objects layer by layer from powder or wire feedstock.

- CNC Machining removes material from a solid block using cutting tools.

2. Precision & Tolerances

- CNC machining typically offers tighter tolerances, often up to ±0.005 mm.

- Metal 3D printing tolerances are improving, but generally less precise without post-processing.

3. Surface Finish

- CNC machining can achieve smooth, high-quality finishes straight from the machine.

- Metal 3D printing often requires secondary machining or polishing for smooth surfaces.

4. Design Complexity

- Metal 3D printing can create internal channels, lattice structures, and other complex geometries without extra cost.

- CNC machining is limited by tool access and cutting paths.

5. Material Waste & Efficiency

- Metal 3D printing is more material-efficient, as it only uses what is needed for the part.

- CNC machining generates more scrap material, although some can be recycled.

6. Production Speed

- CNC machining can be faster for simple parts.

- Metal 3D printing shines in producing intricate parts without tooling delays.

Cost Comparison

Prototyping

- Metal 3D Printing is cost-effective for complex prototypes without the need for tooling.

- CNC Machining may be more affordable for simple prototypes.

Small Batch Production

- Metal 3D printing allows easy customization and rapid iteration.

- CNC machining is efficient for repeatable, moderately complex parts.

Mass Production

- CNC machining is more economical for large quantities due to high production speed.

- Metal 3D printing is generally slower and more expensive for mass production.

When to Choose Metal 3D Printing

- Highly complex geometries

- Lightweight structures with internal features

- Low-volume production with customization

- Aerospace, medical, and R&D applications

When to Choose CNC Machining

- Tight tolerances are critical

- High surface finish requirements

- Medium-to-high volume production

- Strong, fully dense material requirements

Hybrid Manufacturing Approaches

Some manufacturers combine both technologies — using metal 3D printing to create complex preforms and CNC machining for precision finishing. This hybrid approach leverages the strengths of both methods.

Case Studies

- Aerospace: Titanium brackets produced via metal 3D printing reduce weight, then finished with CNC for tight tolerance holes.

- Automotive: Prototype engine components are 3D printed for design validation before CNC machining for functional testing.

- Medical: Custom implants are 3D printed for patient-specific anatomy, then CNC machined for precision fit.

Future Trends

- Improved metal powders and binders for 3D printing

- Faster multi-laser printing systems

- Smarter CNC machines with AI-driven optimization

- Integration of additive and subtractive processes into a single machine

Conclusion

When comparing Metal 3D Printing vs. CNC Machining, it’s clear that both have unique advantages. The choice depends on your priorities: complex geometries and customization favor 3D printing, while high precision and large-scale production suit CNC machining. In many cases, a combination of both yields the best results.

By understanding these differences, manufacturers can select the most effective method to meet their technical, economic, and production goals.