In today’s rapidly evolving manufacturing landscape, CNC machining plays a pivotal role in the robotics industry. From producing high-precision robotic components to enabling automation in machining itself, CNC and robotics are closely intertwined. This article explores the uses, types, and advantages of CNC machining in robotics, designed to help engineers, manufacturers, and procurement professionals understand the full potential of this synergy.

What Is CNC Machining in Robotics?

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses pre-programmed software to control the movement of tools and machinery. In the robotics industry, CNC machining is widely used to create custom parts with tight tolerances, ensuring consistency and reliability in robotic systems.

The integration between CNC machining and robotics works in two ways:

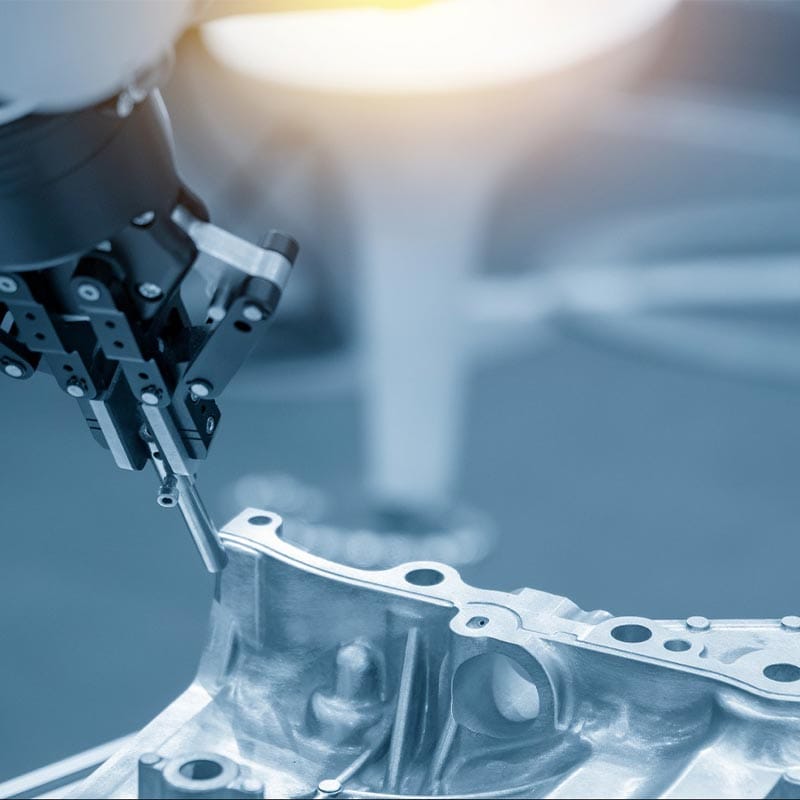

- CNC for Robotics: CNC is used to manufacture high-precision robot parts such as arms, joints, end effectors, brackets, and housings.

- Robotics for CNC: Robots are used in CNC environments for tasks like part loading/unloading, inspection, and finishing—often referred to as “machine tending.”

Key Applications of CNC in Robotics

1. Robotic Arm Components

CNC machining is ideal for producing aluminum or stainless steel components for robotic arms. These parts require high strength, precise geometry, and lightweight properties—critical for dynamic robotic movement.

2. Joints and End Effectors

Robotic joints and grippers must operate smoothly and accurately. CNC-machined parts ensure low-friction surfaces and high load-bearing capabilities, enabling complex robotic tasks such as assembly, packaging, or surgery.

3. Robotic Frames and Structural Parts

Robot housings, frames, and support structures are commonly machined from materials like aluminum or titanium. CNC machining delivers consistent flatness, dimensional accuracy, and durability, especially important in mobile or industrial robots.

4. Prototyping of Robotic Systems

For R&D departments, CNC allows fast and flexible prototyping of robot parts. Engineers can iterate quickly with different materials, including plastics, aluminum, and tool steels.

Benefits of CNC Machining for Robotics

✔ High Precision and Accuracy

CNC machining offers tolerances as tight as ±0.005 mm, making it suitable for delicate robotic assemblies and components that must interact with sensors, gears, and actuators.

✔ Material Versatility

CNC can process a wide range of materials used in robotics, including:

- Aluminum 6061, 7075

- Stainless steel (304, 316)

- Titanium

- Brass

- Engineering plastics (Delrin, PEEK, Nylon)

✔ Repeatability

For batch production of robot parts, CNC ensures dimensional consistency across thousands of units, crucial for scalable robotic deployment.

✔ Short Lead Times

Compared to casting or injection molding, CNC machining can deliver functional robot parts within days, making it ideal for both prototyping and low-volume production.

✔ Automation-Friendly

CNC machining itself can be automated using robotic arms, improving productivity, minimizing human error, and reducing labor costs.

Types of CNC Machining Used in Robotics

Type Description Common Use in Robotics

3-Axis CNC Moves in X, Y, Z directions. Good for basic parts. Flat brackets, housings

5-Axis CNC adds rotational axes. Enables complex part geometry. Robotic joints, curved frames

Swiss Turning Rotational machining with high precision, Small shafts, pins, gears

EDM Machining, Electrical discharge for intricate internal geometries, Micro-holes, internal slots in actuators

Robotic Automation in CNC Machining

While CNC machining is essential for making robots, the inverse is also true—robots are now being used to automate CNC processes. This includes:

- Machine Tending: Robotic arms load and unload raw materials or finished parts from CNC machines.

- Post-Machining Tasks: Robots perform deburring, polishing, or cleaning.

- Inspection & Measurement: Automated inspection systems with vision cameras and CMM probes reduce errors.

- Lights-Out Manufacturing: A fully automated CNC+robot system can run overnight or unattended, maximizing uptime.

Challenges in CNC for Robotics

Despite the many benefits, CNC machining in robotics comes with a few challenges:

- High Initial Cost: Precision CNC machining—especially for aerospace-grade robotic parts—can be costly.

- Complex Geometry: Some robotic designs require advanced 5-axis or EDM machining, increasing the time and complexity.

- Material Constraints: While most metals are machinable, ultra-light composites or carbon fiber may need alternative processing methods.

Future Trends

- AI + CNC: Machine learning is being used to optimize tool paths, predict tool wear, and improve surface finish.

- Hybrid Machines: Some modern machines combine CNC milling and 3D printing to build robotic prototypes faster.

- Miniature Robotics: As microrobotics grows, CNC machining is adapting to smaller scales with micro-tooling.

Industries Using CNC for Robotics

CNC machining is critical in many robotics-related industries:

- Industrial Automation: Assembly robots, welding bots, AGVs

- Medical Robotics: Surgical arms, lab automation

- Consumer Electronics: Smart home robots, cleaning robots

- Aerospace: Space-grade robotics for satellites and drones

- Military & Defense: Reconnaissance robots, unmanned vehicles

Conclusion

CNC machining plays a foundational role in the success of modern robotics. From building precise mechanical parts to enabling automated machining systems, it bridges the gap between design and deployment. As robotic technology continues to evolve, CNCs’ precision, speed, and reliability will remain crucial to innovation and efficiency in this field.

If you’re seeking custom CNC machining services for robotic components, be sure to partner with a supplier experienced in high-tolerance, multi-axis machining and automation-ready production.