In the era of advanced manufacturing, CNC precision machining has emerged as one of the most powerful and transformative processes in modern production. It blends computer control, high-speed cutting, and tight-tolerance capability to create components that meet the most demanding industrial requirements.

From aerospace turbine blades to medical implants and robotic parts, CNC precision machining defines the gold standard for accuracy, repeatability, and efficiency. This comprehensive guide explores how it works, what makes it so effective, and why it continues to drive innovation across global manufacturing.

1. What Is CNC Precision Machining?

CNC precision machining refers to a subtractive manufacturing process where computer-controlled tools remove material from a solid workpiece to form a final part with extremely tight tolerances. “CNC” stands for Computer Numerical Control, which means every motion — from spindle rotation to tool feed rate — is precisely managed by a computer program (G-code).

This process allows manufacturers to achieve tolerances as tight as ±0.001 mm, ensuring consistent quality across large production runs. Typical CNC machines include milling machines, lathes, grinders, and electrical discharge machines (EDM).

Key Features

- High-dimensional accuracy

- Superior surface finish

- Automated, repeatable operations

- Capability with hard materials (steel, titanium, ceramics)

- Complex 3D geometry machining

Whether producing aerospace-grade components or precision prototypes, CNC precision machining guarantees that each part meets strict technical requirements.

2. How CNC Precision Machining Works

The process begins long before the cutting tool meets the material. It starts with CAD design, continues through CAM programming, and ends with final inspection.

Step 1: Computer-Aided Design (CAD)

Engineers design the 3D model of the part using CAD software such as SolidWorks, CATIA, or AutoCAD. Every detail — dimensions, tolerances, and surface finishes — is specified.

Step 2: Computer-Aided Manufacturing (CAM)

The CAD model is converted into toolpaths using CAM software like Mastercam or Fusion 360. This generates the G-code that the CNC machine reads to guide every movement.

Step 3: Setup and Calibration

The machinist mounts the workpiece, installs cutting tools, and ensures that all axes are calibrated. Precision fixturing is critical to avoid vibration and maintain accuracy.

Step 4: Machining Process

The CNC machine automatically executes the program, performing operations such as:

- Milling

- Turning

- Drilling

- Boring

- Grinding

- Thread cutting

Step 5: Quality Inspection

After machining, each component undergoes dimensional verification using tools like CMM (Coordinate Measuring Machine), laser scanners, or optical comparators.

3. Types of CNC Precision Machining Processes

CNC precision machining is not a single method — it’s an umbrella term covering several specialized processes.

3.1 CNC Milling

CNC milling uses rotary cutters to remove material. Machines can move along 3, 4, or 5 axes, allowing intricate shapes and undercuts.

Applications: Mold making, die production, precision housings.

3.2 CNC Turning

Turning involves rotating the workpiece while a stationary tool removes material. It’s ideal for cylindrical parts such as shafts, bushings, and threads.

3.3 CNC Grinding

Used for ultra-smooth surface finishes and precise tolerances. Common in tool manufacturing and finishing hardened components.

3.4 EDM (Electrical Discharge Machining)

EDM removes material using electrical sparks between the tool and the workpiece. It’s suitable for hard metals and complex geometries like deep cavities.

3.5 5-Axis CNC Machining

Allows simultaneous movement along five axes, enabling the production of complex and curved surfaces without repositioning the part.

4. Materials Used in CNC Precision Machining

One of the key advantages of CNC precision machining is its versatility with materials.

MaterialPropertiesApplications

Aluminum Lightweight, corrosion-resistant Automotive, aerospace housings

Steel High strength, durability Gears, shafts, industrial tools

Stainless Steel Corrosion-resistant, biocompatible Medical, marine, food equipment

Titanium Excellent strength-to-weight ratio Aerospace, implants

Copper & Brass Conductive, easy to machine, Electrical connectors

Plastics (POM, ABS, PTFE), Lightweight, chemical resistance, Prototypes, enclosures

5. Advantages of CNC Precision Machining

5.1 Unmatched Accuracy

CNC precision machining delivers exact dimensions that meet even the tightest tolerances required by aerospace and defense industries.

5.2 Repeatability

Once a program is set, every part produced is identical — perfect for mass production and consistency.

5.3 Material Flexibility

Works with metals, plastics, and composites without compromising precision.

5.4 Speed and Efficiency

Modern high-speed machining centers operate continuously, reducing lead times.

5.5 Complex Geometry

Advanced 5-axis systems can produce intricate designs that are impossible with manual machining.

5.6 Reduced Human Error

Automation and digital control minimize deviation caused by human factors.

6. Applications of CNC Precision Machining

CNC precision machining is the backbone of nearly every high-tech industry today.

Aerospace

Manufacturing engine components, turbine blades, and landing gear parts that require micron-level precision.

Automotive

Engine blocks, brake systems, gearboxes, and custom aftermarket components are all produced through CNC machining.

Medical Devices

From surgical tools to orthopedic implants, precision machining ensures biocompatibility and reliability.

Electronics

CNC machining produces heat sinks, connectors, and enclosures for high-performance electronics.

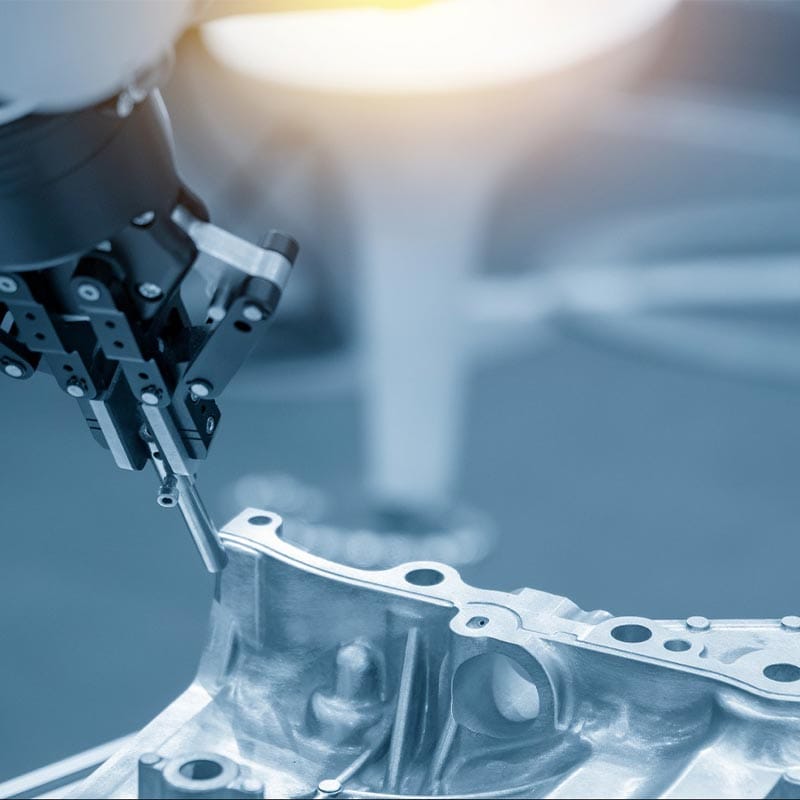

Robotics & Automation

Custom end-effectors, joints, and housings depend on precision components.

Defense and Energy

CNC machining provides the consistency needed for weapons systems, turbines, and energy equipment.

7. CNC Precision Machining vs. Other Manufacturing Processes

FeatureCNC Precision Machining3D Printing (Additive)Casting

Accuracy ±0.001 mm ±0.1 mm ±0.2 mm

Material Range Wide Limited Wide

Surface Finish Excellent Rough Good

Production Speed Moderate Fast for prototypes Fast for mass production

Tooling Cost Medium Low High for molds

While additive manufacturing is ideal for prototypes, CNC precision machining remains superior for final parts requiring strength, precision, and reliability.

8. The Role of Automation and AI in CNC Precision Machining

With Industry 4.0, CNC precision machining has become even more intelligent.

Modern factories integrate:

- Robotic loading systems

- Smart tool monitoring

- Predictive maintenance using AI

- Cloud-based production tracking

These innovations not only boost productivity but also reduce downtime and waste — aligning with sustainable manufacturing goals.

9. Quality Control in CNC Precision Machining

Quality is non-negotiable. Every CNC precision machining factory implements strict inspection protocols:

- In-process measurement systems

- CMM inspection reports

- Surface roughness tests

- Statistical Process Control (SPC)

Manufacturers must also comply with certifications like ISO 9001, AS9100, or ISO 13485 for medical components.

10. How to Choose the Right CNC Precision Machining Partner

When outsourcing CNC precision machining, consider:

- Experience in your industry

- Available equipment (3-, 4-, 5-axis machines)

- Material expertise

- Tolerance capabilities

- Quality control standards

- Delivery and communication reliability

Partnering with a reputable CNC precision machining company ensures your components are produced on time, within budget, and according to specification.

11. Future Trends in CNC Precision Machining

The next decade will see a massive transformation through:

- Hybrid manufacturing (CNC + 3D printing)

- AI-driven adaptive machining

- Digital twin simulation

- Eco-friendly coolants and energy-efficient systems

- Full automation with smart robotics

CNC precision machining will continue to lead the evolution toward smarter, cleaner, and faster manufacturing.

12. Frequently Asked Questions (FAQ)

Q1: What tolerance can CNC precision machining achieve?

Typically between ±0.005 mm and ±0.001 mm, depending on the machine and material.

Q2: Is CNC precision machining cost-effective for small batches?

Yes, it’s ideal for both prototypes and small-volume production due to fast setup and high repeatability.

Q3: Which industries rely most on CNC precision machining?

Aerospace, automotive, medical, electronics, robotics, and defense.

Q4: What’s the difference between CNC machining and manual machining?

CNC machining is automated, consistent, and capable of producing far more complex geometries than manual methods.

Q5: Can CNC machines work with non-metal materials?

Absolutely — plastics, composites, and even ceramics can be machined precisely.

Conclusion

CNC precision machining is the foundation of modern manufacturing — combining automation, accuracy, and innovation.

It transforms digital designs into real-world components with exceptional precision, supporting industries from aerospace to medical technology.

As technology advances, the integration of AI, robotics, and smart monitoring will only make CNC precision machining faster, more sustainable, and more capable of meeting future engineering challenges.

Whether you are designing prototypes or scaling mass production, CNC precision machining remains the most dependable path toward high-quality, high-performance parts.