1. Introduction: What Is CNC Rapid Prototyping?

CNC rapid prototyping is a precision manufacturing process that combines computer numerical control (CNC) machining with rapid production techniques to create functional prototypes and low-volume parts directly from digital 3D CAD models.

Unlike traditional manufacturing that requires tooling or molds, CNC rapid prototyping allows engineers to quickly produce physical components with tight tolerances, excellent surface finishes, and high dimensional accuracy—making it ideal for product validation, mechanical testing, and design iteration.

By using CNC machining centers (milling, turning, drilling, and EDM), manufacturers can achieve high-speed material removal and produce prototypes from real engineering materials, including metals and plastics. This makes CNC prototyping a crucial bridge between concept and production.

2. How CNC Rapid Prototyping Works

The CNC rapid prototyping process begins with a 3D CAD model designed by engineers or product developers. The following steps outline the workflow:

- 3D Model Preparation – Designers create detailed CAD files with complete geometrical and tolerance data.

- CAM Programming – The CAD model is converted into CNC toolpaths using Computer-Aided Manufacturing software.

- Machine Setup – Workpieces are fixed to CNC milling or turning machines using custom jigs or clamps.

- Machining Operations – High-speed cutting tools remove material layer by layer, following the programmed path.

- Inspection and Finishing – Finished prototypes undergo dimensional inspection, polishing, or surface treatment.

- Testing and Validation – The prototypes are tested for form, fit, and function before design approval.

This entire process can be completed within hours or days, depending on part complexity—offering far greater speed than traditional mold-based methods.

3. CNC Prototyping vs. 3D Printing

While both CNC rapid prototyping and 3D printing (additive manufacturing) are essential tools in modern product development, they differ fundamentally:

AspectCNC Rapid Prototyping3D Printing (Additive Manufacturing)

Process Type: Subtractive (removes material), Additive (adds material)

Material Range: Metals, plastics, composites. Mostly plastics, limited metals

Tolerances ±0.01 mm (high precision) ±0.1 mm (lower precision)

Surface Finish Excellent Requires post-processing

Strength and Functionality Functional and strong Prototype-only (in most cases)

Production Speed Fast for single parts Fast for complex geometries

CNC prototyping excels in accuracy, mechanical performance, and finish quality, making it the preferred method for functional prototypes and engineering validation models.

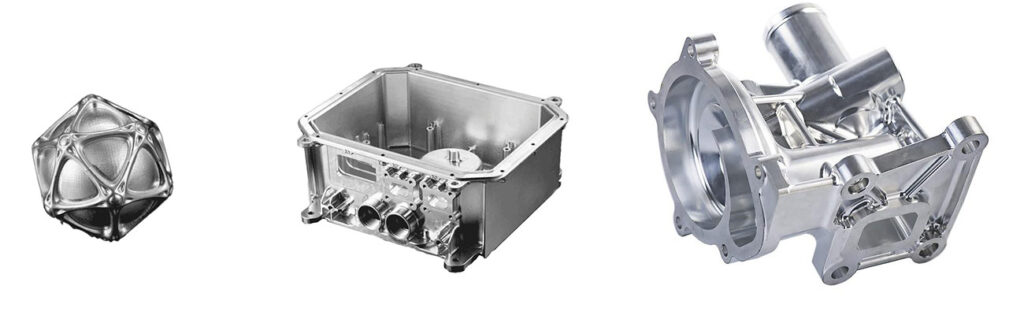

4. Main Processes in CNC Rapid Prototyping

CNC rapid prototyping utilizes multiple machining operations depending on part design:

a. CNC Milling

Removes material using rotating multi-axis cutting tools. Perfect for creating complex surfaces, pockets, and contours.

b. CNC Turning

Ideal for cylindrical parts, shafts, and components requiring rotational symmetry.

c. CNC Drilling

Used to produce precise holes with controlled depth and diameter.

d. Electrical Discharge Machining (EDM)

Applicable for high-precision components made from conductive metals.

e. CNC Grinding

Refines the surface for high-accuracy fits and fine finishes.

Each process can be combined to create fully functional prototypes that match production-quality standards.

5. Materials Used in CNC Rapid Prototyping

CNC prototyping supports a broad range of materials, giving engineers flexibility to test various functional properties.

Metals

- Aluminum (6061, 7075, 2024) – Lightweight, corrosion-resistant, easy to machine.

- Stainless Steel (304, 316, 17-4PH) – High strength and excellent surface quality.

- Brass and Copper – Great conductivity and aesthetics.

- Titanium – Strong and biocompatible, used in aerospace and medical parts.

Plastics

- ABS – Tough, low-cost, used for general-purpose prototypes.

- POM (Delrin) – Excellent for precision gears and mechanical components.

- Nylon (PA6, PA66) – Strong, flexible, and wear-resistant.

- PMMA (Acrylic) – Transparent and ideal for optical parts.

- PEEK – High-performance polymer for aerospace and medical applications.

6. Benefits of CNC Rapid Prototyping

CNC rapid prototyping provides a combination of speed, precision, and material flexibility unmatched by most other manufacturing methods.

Key Advantages

- High Dimensional Accuracy – Achievable tolerances up to ±0.01 mm.

- Fast Turnaround Time – Complex prototypes can be ready within days.

- Real Material Properties – Functional prototypes behave like final products.

- No Tooling Required – Ideal for low-volume runs and iterative designs.

- Superior Surface Finish – Ready for testing or direct assembly.

- Scalable for Production – Same equipment can produce small-batch parts.

- Compatibility – Works with metals, plastics, and hybrid materials.

7. Applications Across Industries

CNC rapid prototyping is widely adopted across multiple high-precision industries:

- Aerospace and Defense – Aircraft brackets, turbine components, and fixtures.

- Automotive – Engine housings, transmission cases, and dashboard components.

- Electronics – Enclosures, heat sinks, and connectors.

- Medical Devices – Surgical instruments, prosthetics, and implant components.

- Robotics – Structural arms, end effectors, and sensor housings.

- Consumer Products – Prototype casings and functional assemblies.

It enables companies to validate designs early, reduce time-to-market, and accelerate innovation.

8. Design Considerations for CNC Prototype Parts

To ensure success in CNC rapid prototyping, designers should follow several best practices:

- Avoid deep cavities to prevent tool deflection.

- Maintain consistent wall thickness to reduce vibration.

- Round internal corners instead of sharp edges.

- Use standard hole sizes for faster machining.

- Specify tolerances realistically—not tighter than necessary.

- Consider the machining direction for surface quality.

These considerations not only improve machinability but also reduce cost and lead time.

9. Surface Finishing Options

CNC prototypes can be finished using various surface treatments to improve appearance and performance:

- Anodizing (Type II or III) – Enhances corrosion resistance and color finish.

- Bead Blasting – Produces uniform matte texture.

- Powder Coating – Adds durability and color.

- Polishing – For mirror-like finishes.

- Electroplating – Adds conductivity or decorative effects.

- Laser Marking – Permanent identification or branding.

Finishing enhances both aesthetics and functional durability, especially for customer-facing prototypes.

10. Challenges and Solutions in CNC Rapid Prototyping

While CNC rapid prototyping is reliable, it comes with technical challenges:

ChallengeSolution

Tool wear during long machining cycles. Regular tool monitoring and replacement

Material deformation (especially plastics): Use low feed rates and coolant control.

Surface burrs on soft metals: Deburring and precision finishing

Long setup times for complex parts, Multi-axis CNC, and quick-change fixtures

Skilled machinists and optimized CAM programming can mitigate these issues efficiently.

11. CNC Rapid Prototyping in Low-Volume Production

CNC rapid prototyping is not limited to one-off samples. It’s increasingly used in low-volume production for specialized markets, such as medical devices, robotics, and industrial automation.

Advantages for low-volume manufacturing:

- No expensive molds or tooling required.

- Flexible customization between batches.

- Faster delivery compared to injection molding.

- Consistent quality across multiple runs.

This hybrid approach—prototyping and production on the same platform—allows manufacturers to transition seamlessly from concept to commercialization.

12. Future Trends in CNC Rapid Prototyping

The future of CNC rapid prototyping is shaped by automation, digitalization, and sustainability:

- AI-powered CAM optimization – Reduces machining time and waste.

- Hybrid additive-subtractive systems – Combine 3D printing with CNC finishing.

- Real-time process monitoring – Improves accuracy and traceability.

- Eco-friendly coolants – Support green manufacturing initiatives.

- Integration with IoT and Industry 4.0 – Enables smart, connected factories.

These innovations make CNC rapid prototyping more efficient and environmentally sustainable.

13. FAQs About CNC Rapid Prototyping

Q1: What is CNC rapid prototyping used for?

It’s used to create accurate, functional prototypes for testing, design validation, and short-run production.

Q2: How fast can CNC prototypes be made?

Typically, within 1–5 days, depending on part complexity and material.

Q3: What materials can be used for CNC rapid prototyping?

Common materials include aluminum, stainless steel, ABS, nylon, and POM.

Q4: What tolerances are achievable?

±0.01 mm for metals and ±0.05 mm for plastics.

Q5: Can CNC prototypes be used for final production?

Yes, many low-volume parts are produced using the same CNC setups.

Q6: What’s the difference between CNC rapid prototyping and injection molding?

CNC is faster and doesn’t require molds, making it ideal for prototypes and small batches.

Q7: Is CNC prototyping expensive?

It’s cost-effective for small runs and complex parts without tooling investment.

Q8: How does CNC prototyping compare to 3D printing?

CNC delivers higher precision, material strength, and better surface finish.

Q9: Can CNC rapid prototyping handle large parts?

Yes, depending on the machine size and material type.

Q10: What industries use CNC rapid prototyping?

Aerospace, automotive, medical, electronics, robotics, and consumer goods.

Q11: Is post-processing required?

Optional—surface finishing enhances appearance and performance.

Q12: Can multiple materials be combined in CNC prototyping?

Yes, through assembly or hybrid machining setups.

14. Conclusion

CNC rapid prototyping stands at the forefront of modern product development—merging precision, speed, and flexibility.

It empowers engineers to iterate faster, validate designs accurately, and accelerate time-to-market with real, functional parts.

By leveraging CNC machining technologies, manufacturers can move seamlessly from concept to prototype to production, ensuring quality, performance, and innovation at every stage.