In today’s advanced manufacturing landscape, precision, durability, and high performance are no longer optional—they are essential. One of the key technologies enabling this transformation is ceramic CNC machining.

What Is Ceramic CNC Machining?

Definition

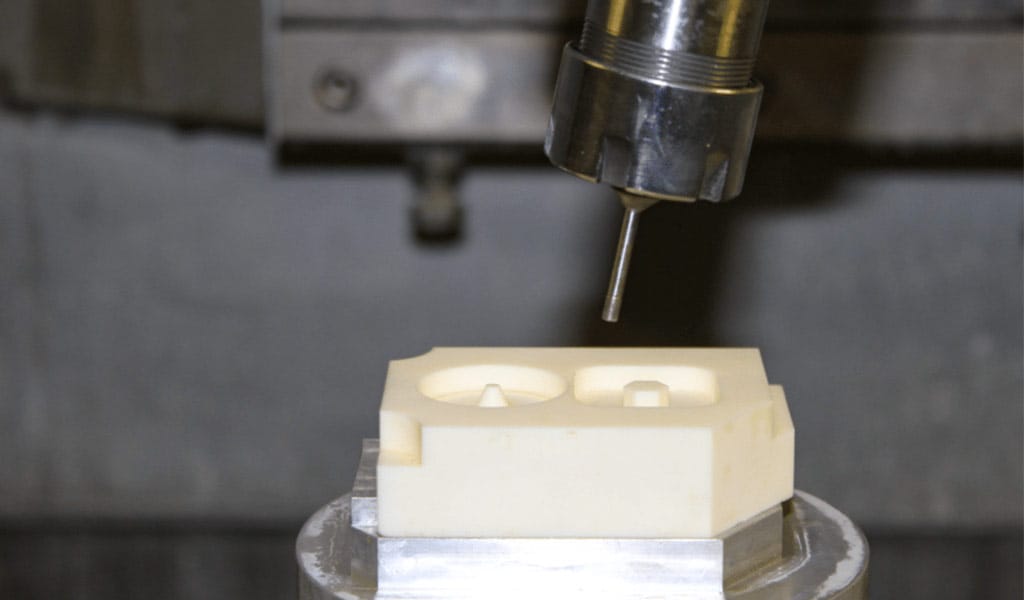

Ceramic CNC machining refers to the use of computer numerical control (CNC) machines to precisely shape and finish ceramic materials into functional parts.

Why It Matters

Ceramics provide exceptional hardness, thermal stability, and corrosion resistance, making them indispensable for industries where conventional materials fall short.

Properties of Ceramics That Impact Machining

- Extreme hardness

- Brittleness

- High thermal resistance

- Chemical inertness

- Electrical insulation

Common Ceramics Used in CNC Machining

Alumina (Al₂O₃)

Applications: insulators, implants, cutting tools.

Zirconia (ZrO₂)

Applications: dental prosthetics, bearings, surgical tools.

Silicon Carbide (SiC)

Applications: aerospace, seals, high-temp parts.

Silicon Nitride (Si₃N₄)

Applications: automotive engines, bearings, tools.

Machinable Glass Ceramics (MGC)

Applications: prototypes, custom parts, low-stress uses.

Processes in Ceramic CNC Machining

CNC Milling

- Complex geometries

- Tight tolerances

CNC Turning

- Cylindrical parts

- Requires careful cooling

Grinding

- Fine surface finishes

- Ra ≤ 0.2 µm achievable

Drilling

- Diamond drills under strict controls

Ultrasonic-Assisted Machining

- Reduces cutting forces

- Extends tool life

Laser Machining

- Micromachining and thin ceramics

- Non-contact, less cracking risk

Applications of Ceramic CNC Machining

Aerospace

- Turbine blades, nozzles, thermal shields

Medical

- Implants, crowns, and surgical instruments

Electronics

- Substrates, insulators, sensors

Automotive

- Engine parts, seals, spark plugs

Industrial Equipment

- Valves, pumps, bearings, wear parts

Advantages of Ceramic CNC Machining

- High precision (±0.01 mm)

- Long component lifespan

- Complex design capabilities

- Superior strength-to-weight ratio

- Excellent surface finishes

Challenges of Ceramic CNC Machining

- Tool wear (diamond tools are costly)

- Brittleness and fracture risks

- High processing costs

- Limited scalability for mass production

Ceramic CNC Machining vs. Other Methods

CNC Machining vs. Injection Molding

- Machining = flexibility, precision

- Molding = mass production efficiency

CNC Machining vs. 3D Printing

- CNC = tighter tolerances, better finishes

- 3D printing = more design freedom

CNC Machining vs. Pressing and Sintering

- Machining = complex, post-sintering designs

- Pressing/sintering = simpler, high volume

Future Trends in Ceramic CNC Machining

- Hybrid machining (CNC + ultrasonic/laser)

- Advanced tooling (longer-life diamond tools)

- Automation and robotics

- New ceramic materials (tougher, easier to machine)

- Sustainable manufacturing

Frequently Asked Questions (FAQ)

Q1: What tolerance can ceramic CNC machining achieve?

As tight as ±0.01 mm.

Q2: Which ceramics are most commonly used?

Alumina, zirconia, silicon carbide, silicon nitride, and machinable glass ceramics.

Q3: Is it more expensive than metal machining?

Yes, but the longevity of parts offsets the cost.

Q4: Can custom designs be manufactured?

Yes, CNC allows complex, custom geometries.

Q5: Which industries rely most on ceramic CNC machining?

Aerospace, medical, electronics, automotive, and industrial sectors.

Conclusion

Ceramic CNC machining has transformed high-performance manufacturing by making it possible to produce precise, durable, and complex ceramic components. Despite challenges, its role in aerospace, medical, and electronics is indispensable. With continuous innovation, ceramic CNC machining will remain a cornerstone of precision engineering for decades to come.