The manufacturing world is undergoing a rapid transformation, driven by the demand for faster, more precise, and cost-effective production solutions. At the heart of this transformation is the CNC machining company — a specialized manufacturer equipped with computer-controlled machines capable of producing highly accurate parts for diverse industries.

Whether your business is in aerospace, automotive, robotics, medical devices, or electronics, the choice of a CNC machining company can determine whether your product meets strict quality standards or falls short. This comprehensive guide will help you understand what makes a CNC machining company exceptional, what services they offer, how to evaluate potential partners, and the global landscape of CNC manufacturing in 2025.

Chapter 1: What is a CNC Machining Company?

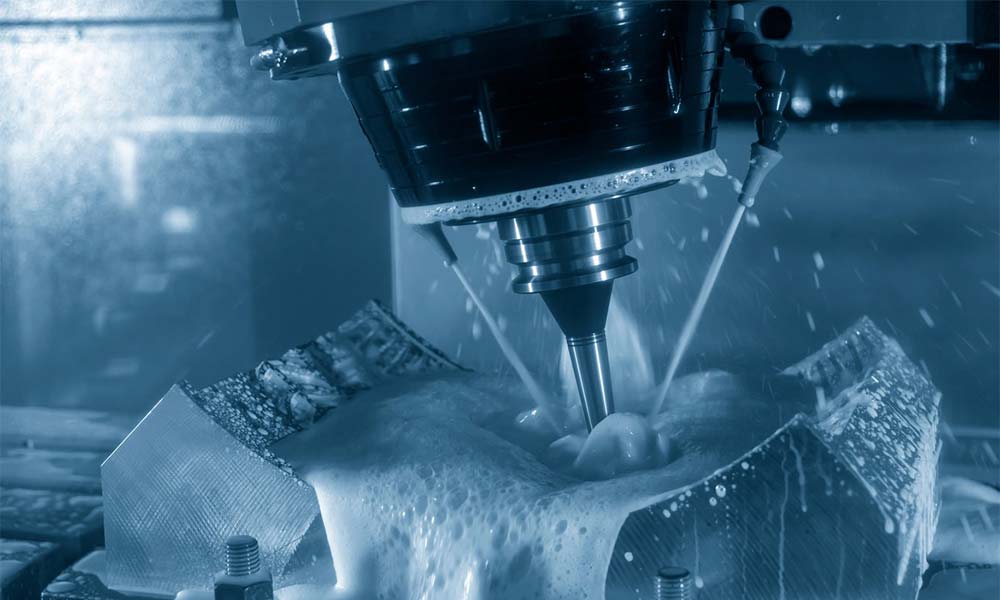

A CNC machining company specializes in producing components using CNC (Computer Numerical Control) machines — advanced tools that follow digital instructions to cut, shape, drill, and finish materials with unmatched precision. These companies combine engineering expertise, modern equipment, and stringent quality control processes to create parts for demanding applications.

Key Characteristics of a CNC Machining Company

- Operates CNC milling, turning, drilling, and grinding machines.

- Works with a wide range of materials, including metals, plastics, and composites.

- Provides both prototype and mass production capabilities.

- Maintains tight tolerances (often as small as ±0.005 mm).

- Offers additional services like surface finishing, heat treatment, and assembly.

Chapter 2: Core Services Provided

A reputable CNC machining company will typically offer:

1. CNC Milling

Multi-axis milling machines remove material from a workpiece to create complex shapes, slots, and holes.

2. CNC Turning

Best for cylindrical or symmetrical parts, CNC turning ensures consistent diameters and smooth surfaces.

3. Precision Prototyping

Allows customers to test part designs before committing to mass production.

4. Low-Volume and Mass Production

Flexible batch sizes to suit startups, SMEs, and large enterprises.

5. Secondary Services

Anodizing, powder coating, polishing, and assembly services to deliver finished, ready-to-use parts.

Chapter 3: Advantages of Choosing a CNC Machining Company

- Precision: Digital control ensures repeatability and accuracy.

- Material Versatility: From aluminum and stainless steel to titanium and PEEK.

- Scalability: Adaptable for both one-off prototypes and large production runs.

- Reduced Waste: Optimized cutting paths minimize material loss.

- Speed: Automated processes shorten lead times significantly.

Chapter 4: Industry Applications

Aerospace

Engine components, structural brackets, and landing gear parts.

Automotive

Custom gears, drive shafts, and prototype engine components.

Robotics

Robot arms, precision frames, and gear housings.

Medical

Surgical tools, orthopedic implants, and diagnostic equipment.

Electronics

Heat sinks, casings, and precision connectors.

Chapter 5: The CNC Machining Process

A typical CNC machining company follows these steps:

- Design & CAD Modeling

- CAM Programming

- Material Selection

- Machining Operations

- Quality Inspection (CMM, laser scanning)

- Surface Finishing

- Packaging & Delivery

Chapter 6: Cost Factors When Hiring a CNC Machining Company

Several factors affect pricing:

- Material Type (titanium vs. aluminum)

- Part Complexity

- Tolerance Requirements

- Production Volume

- Surface Finishing Needs

- Lead Time Urgency

Example: A small aluminum prototype may cost $50–$150, while a complex aerospace titanium part can exceed $1,000 per unit.

Chapter 7: How to Choose the Right CNC Machining Company

- Industry Experience

- Certifications (ISO 9001, AS9100, IATF 16949)

- Equipment Capability

- Quality Control Systems

- Customer Reviews & Case Studies

- Communication & Responsiveness

- Global vs. Local Supplier Considerations

Chapter 8: Global CNC Machining Company Comparison (2025)

RegionStrengthsExamples

USA High-quality aerospace & defense parts Xometry, Protolabs

Germany Engineering precision & automotive DMG Mori partners

China Cost-effective large-scale production YD Rapid, WayKen

Japan Ultra-precision electronics parts Okuma partners

Singapore High-tech robotics & medical Meiban, Beyonics

Chapter 9: Technology Trends

- 5-Axis CNC Machining

- AI-Assisted CAM Programming

- Robotics-Integrated Machining Cells

- IoT-Enabled Machine Monitoring

- Hybrid Additive-Subtractive Machining

Chapter 10: Common Customer Questions

Q: How fast can a CNC machining company deliver parts?

A: Prototyping can be as fast as 3–5 days; production runs may take 2–4 weeks.

Q: Can they handle small batches?

A: Yes, many companies specialize in low-volume, high-mix production.

Q: What tolerances can be achieved?

A: ±0.005 mm is common, with some companies offering ±0.002 mm for ultra-precision work.

Conclusion

A CNC machining company is more than just a manufacturing service provider — it’s a partner in innovation and product quality. By understanding their capabilities, industry focus, and technology adoption, you can select a company that meets your project’s exact requirements and budget.

If you want precision, speed, and reliability, choose a CNC machining company that combines advanced technology with engineering expertise.