Bronze has been a trusted engineering material for centuries due to its excellent strength, corrosion resistance, and low friction properties. Today, with the rise of advanced CNC technologies, CNC machining bronze has become an essential process in producing high-precision components for aerospace, marine, electrical, and industrial applications. This complete guide explores everything you need to know about machining bronze using CNC technology — from material selection to machining techniques, industry applications, and design optimization.

What is CNC Machining Bronze?

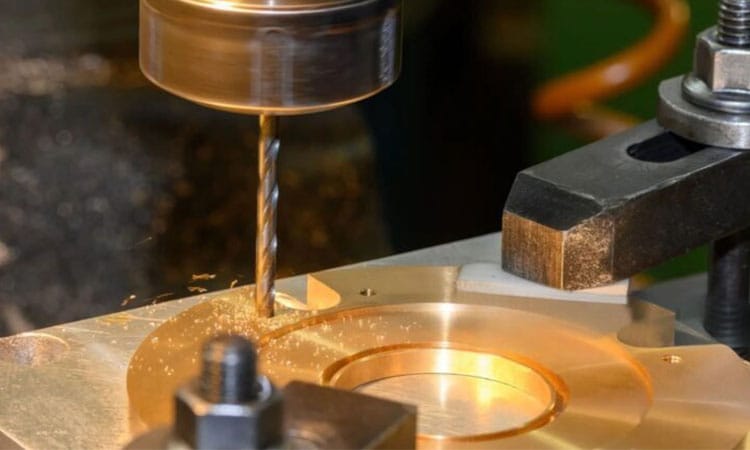

CNC machining bronze refers to the process of cutting and shaping bronze alloys using computer numerical control (CNC) machines. These machines follow pre-programmed instructions to execute highly precise movements with exceptional repeatability. Bronze’s machinability, combined with CNC technology, makes it possible to create complex components with tight tolerances and consistent quality.

This method is especially effective for producing bronze parts such as:

- Bushings and bearings

- Gears and gear blanks

- Marine propellers and shafts

- Valve components and fittings

- Electrical contacts and connectors

The compatibility of bronze with CNC machining helps manufacturers meet the high-performance standards required in modern mechanical systems.

Why Choose CNC Machining for Bronze?

There are several reasons why CNC machining bronze is a preferred method for producing custom parts:

1. Excellent Machinability

Bronze alloys generally have good machinability, especially compared to stainless steel or titanium. This allows for faster machining times and better surface finishes.

2. Durability and Strength

Bronze components exhibit superior wear resistance and load-bearing capacity, making them ideal for heavy-duty applications.

3. Corrosion Resistance

Many bronze alloys are resistant to seawater, chemicals, and oxidation, extending part lifespan in harsh environments.

4. Dimensional Accuracy

CNC machines ensure micron-level precision, ideal for components that require tight tolerances and exact fits.

By combining the inherent qualities of bronze with the precision of CNC systems, manufacturers achieve reliable, long-lasting parts with minimal waste and reduced labor time.

Common Bronze Alloys Used in CNC Machining

There are several bronze alloys suitable for CNC machining. Each offers different mechanical properties, corrosion resistance, and cost levels.

AlloyPropertiesCommon Applications

Phosphor Bronze (C510, C544) Excellent fatigue resistance, good conductivity Electrical components, springs

Aluminum Bronze (C954, C955) High strength, corrosion-resistant Marine hardware, pump parts

Bearing Bronze (C932, SAE 660) Low friction, good wear resistance Bushings, bearings, sleeves

Silicon Bronze (C655) Weldable, strong, corrosion-resistant Architectural, marine

Selecting the correct bronze alloy is a critical step in optimizing CNC machining bronze for specific performance requirements.

CNC Machining Techniques for Bronze

The CNC machining process typically includes a series of operations designed to shape bronze materials into finished parts. Common techniques include:

● Turning

Ideal for producing cylindrical parts like bushings or valve stems. Bronze’s low friction helps maintain smooth cuts.

● Milling

Used for complex geometries, flat surfaces, pockets, and slots. Multi-axis CNC milling can create intricate parts with great accuracy.

● Drilling

Bronze allows clean and fast drilling, especially when sharp tools and proper feeds are used.

● Threading and Tapping

Threaded features are common in fittings and connectors. CNC machines ensure precise pitch and alignment.

● Surface Finishing

Polishing, deburring, and surface coating can enhance corrosion resistance and appearance.

To optimize CNC machining of bronze, tool selection is crucial. Carbide or coated tools are preferred for extending tool life and achieving clean finishes.

Design Considerations for Bronze CNC Parts

When designing components for CNC machining bronze, consider the following:

- Allowable Tolerances: Bronze alloys can hold tolerances as tight as ±0.001 inches with proper tooling.

- Wall Thickness: Avoid overly thin sections that could deform during machining.

- Thermal Expansion: Bronze expands more than steel under heat, which must be considered for high-temperature applications.

- Burr Formation: Some bronze alloys produce fine burrs during cutting; post-machining deburring is often required.

Collaboration between design engineers and CNC machinists helps avoid costly design flaws and maximizes manufacturability.

Applications of CNC Machined Bronze Parts

Bronze parts produced with CNC machining are widely used in industries such as:

- Marine Industry: Propellers, pump components, and shaft sleeves due to corrosion resistance.

- Aerospace: Bushings, valve seats, and high-load joints.

- Automotive: Brake components, bearings, and fuel system parts.

- Electronics: Precision terminals, connectors, and springs.

- Heavy Equipment: Wear plates, gears, and hydraulic components.

The versatility of CNC machining bronze ensures that it continues to serve a broad range of demanding engineering applications.

Best Practices for CNC Machining Bronze

To achieve optimal results, manufacturers should follow these best practices:

- Use carbide tools with sharp cutting edges.

- Apply flood coolant or air blast to avoid chip welding and tool overheating.

- Optimize cutting speeds and feed rates based on specific bronze alloy properties.

- Inspect parts using coordinate measuring machines (CMM) to confirm tolerances.

- Finish parts with polishing, sandblasting, or coating as required.

These steps ensure that every bronze component meets quality, durability, and performance standards.

Conclusion

CNC machining bronze offers an ideal solution for manufacturers seeking high-precision, corrosion-resistant, and wear-tolerant components. Whether you’re working in aerospace, marine, or heavy machinery, bronze alloys deliver dependable performance and long service life.

By selecting the right alloy, applying optimal machining parameters, and following best practices, CNC shops can consistently produce bronze parts that meet the strictest industry demands.