The aerospace industry demands unparalleled precision, durability, and reliability in every component. Aerospace parts CNC machining is the backbone of modern aircraft manufacturing, enabling the production of complex, high-tolerance parts with exceptional accuracy. From turbine blades to structural components, CNC (Computer Numerical Control) machining ensures that aerospace parts meet stringent industry standards.

This comprehensive guide explores the importance of aerospace parts CNC machining, the materials used, key manufacturing processes, and the future of aerospace manufacturing.

Why CNC Machining is Essential for Aerospace Parts

1. Unmatched Precision and Accuracy

Aircraft components must operate flawlessly under extreme conditions. Aerospace parts CNC machining achieves micron-level tolerances (often within ±0.0001 inches), ensuring perfect fit and function.

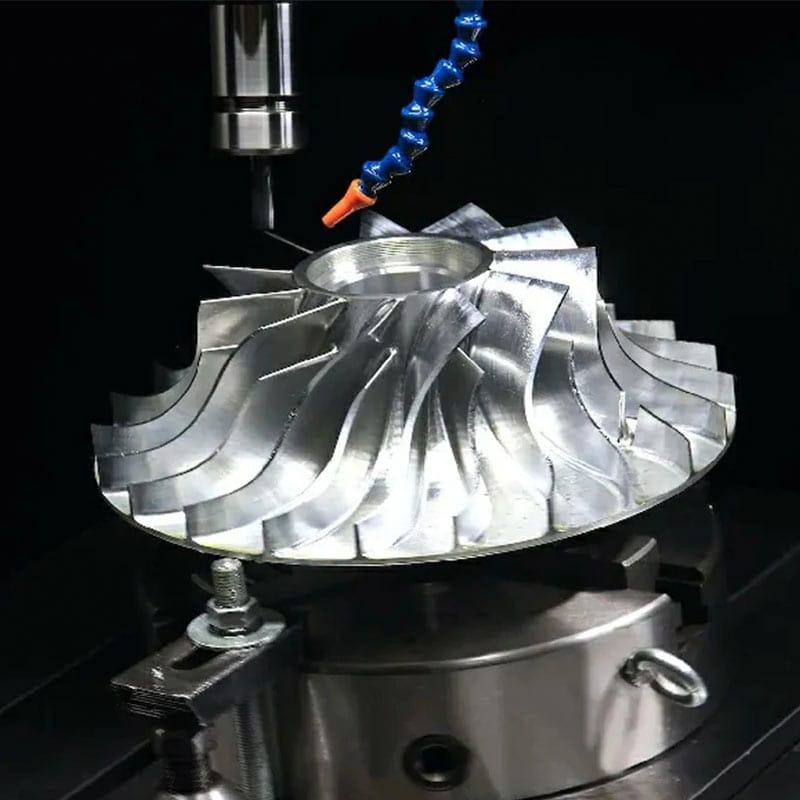

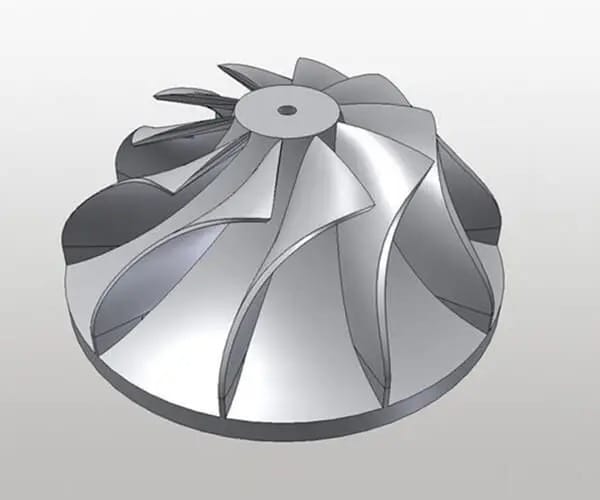

2. Complex Geometries Made Possible

Traditional machining struggles with intricate aerospace designs. CNC machines, using 5-axis capabilities, produce complex shapes like turbine blades, fuel nozzles, and landing gear components with ease.

3. Superior Material Compatibility

Aerospace-grade materials like titanium, Inconel, and aluminum alloys are notoriously difficult to machine. CNC technology handles these materials efficiently while maintaining structural integrity.

4. Repeatability and Scalability

CNC machining ensures every part is identical, critical for mass production in aerospace manufacturing. Automated processes reduce human error and enhance consistency.

5. Reduced Waste and Cost Efficiency

Precision machining minimizes material waste, lowering production costs. Advanced CAM (Computer-Aided Manufacturing) software optimizes tool paths for maximum efficiency.

Key Aerospace Parts Produced via CNC Machining

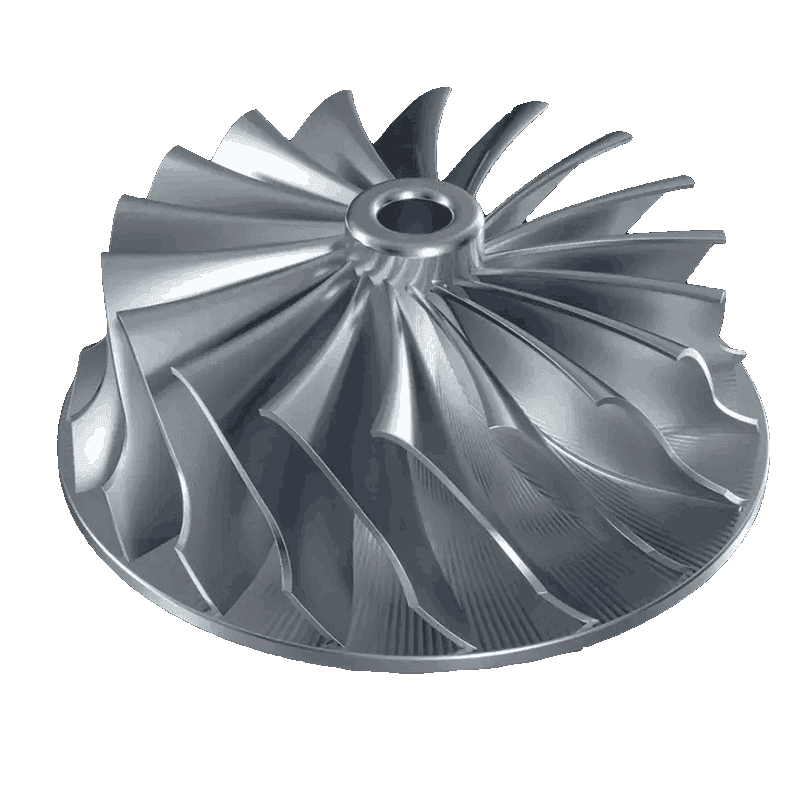

1. Turbine Blades and Engine Components

Jet engines require ultra-precise blades and housings. CNC machining ensures aerodynamic efficiency and thermal resistance.

2. Structural Components (Brackets, Frames, Ribs)

Aircraft frames demand lightweight yet strong parts. CNC-machined aluminum and titanium alloys provide the perfect balance.

3. Landing Gear Parts

High-strength steel and titanium landing gear components must withstand immense stress. CNC machining guarantees durability and fatigue resistance.

4. Avionics and Control System Housings

Precision-machined enclosures protect sensitive electronics from vibration and extreme temperatures.

5. Fuel System Components

Leak-proof fittings, valves, and pumps are critical for safety. CNC machining ensures airtight tolerances.

Materials Used in Aerospace Parts CNC Machining

1. Titanium (Ti-6Al-4V)

- High strength-to-weight ratio

- Corrosion-resistant

- Used in airframes and engine parts

2. Aluminum Alloys (7075, 2024)

- Lightweight yet strong

- Ideal for structural components

3. Inconel (718, 625)

- Heat-resistant superalloy

- Used in turbine engines and exhaust systems

4. Stainless Steel (17-4PH, 304)

- High corrosion resistance

- Common in fasteners and hydraulic systems

5. Composites (CFRP, GFRP)

- Increasingly used for weight reduction

- CNC machining ensures precise trimming and drilling

Advanced CNC Machining Techniques for Aerospace

1. 5-Axis CNC Machining

- Allows simultaneous machining from multiple angles

- Reduces setup time and improves accuracy

2. High-Speed Machining (HSM)

- Faster cutting speeds without sacrificing precision

- Ideal for thin-walled aerospace components

3. Swiss-Type CNC Machining

- Perfect for small, high-precision parts like fasteners and connectors

4. EDM (Electrical Discharge Machining)

- Used for hard metals like Inconel

- Produces intricate shapes without tool wear

5. Additive Manufacturing (Hybrid CNC)

- Combines 3D printing with CNC finishing

- Reduces material waste and speeds up prototyping

Quality Control in Aerospace CNC Machining

1. CMM (Coordinate Measuring Machines)

- Verifies dimensional accuracy

- Ensures compliance with aerospace standards

2. Non-Destructive Testing (NDT)

- X-ray, ultrasonic, and dye penetrant inspections

- Detects hidden defects without damaging parts

3. Surface Finish Analysis

4. Statistical Process Control (SPC)

- Real-time monitoring of machining parameters

- Ensures consistency and identifies deviations early

5. First Article Inspection (FAI)

- Rigorous testing of initial production samples

- Validates that parts meet engineering specifications

Challenges in Aerospace Parts CNC Machining

1. Tight Tolerances & Complex Geometries

- Aerospace components often require tolerances within ±0.0005 inches

- Multi-axis CNC machines and advanced tooling are essential

2. Heat & Stress Management

- High-speed machining generates heat, which can warp materials

- Coolant systems and optimized cutting strategies mitigate thermal distortion

3. Material Hardness & Tool Wear

- Titanium and Inconel are abrasive, leading to rapid tool degradation

- Diamond-coated and carbide tools extend tool life

4. Regulatory Compliance (AS9100, NADCAP)

- Aerospace manufacturers must adhere to strict industry certifications

- Documentation and traceability are critical

5. Cost & Lead Time Pressures

- Balancing precision with production efficiency is key

- Automation and AI-driven machining help reduce costs

Future Trends in Aerospace CNC Machining

1. AI & Machine Learning Optimization

- Predictive maintenance reduces downtime

- Adaptive machining adjusts parameters in real-time

2. Digital Twin Technology

- Virtual simulations optimize machining processes before production

- Reduces trial-and-error waste

3. Sustainable Machining Practices

- Recycling metal chips and using eco-friendly coolants

- Energy-efficient CNC machines lower the carbon footprint

4. Hybrid Manufacturing (Additive + CNC)

- 3D-printed near-net shapes finished with CNC precision

- Reduces material waste and speeds up production

5. Smart Factories & IoT Integration

- Connected CNC machines enable remote monitoring.

- Real-time data improves quality control.

Aerospace parts CNC machining is the cornerstone of modern aviation, delivering the precision, strength, and reliability required for flight-critical components. From turbine blades to structural frames, CNC technology ensures that aerospace manufacturers meet the industry’s most demanding standards.

As advancements in AI, automation, and hybrid manufacturing continue, the future of aerospace parts CNC machining promises even greater efficiency, sustainability, and innovation.

For aerospace engineers and manufacturers, investing in high-precision CNC machining is not just an option—it’s a necessity for staying competitive in an industry where failure is not an option.