Custom aluminum parts are precision-engineered components fabricated from aluminum or its alloys, tailored to meet specific design, functional, or application requirements. These parts are manufactured through processes such as CNC machining, extrusion, casting (die casting, sand casting), or stamping, depending on the complexity, tolerances, and volume needed.

Key Advantages

- Lightweight (~1/3 the weight of steel)

- Corrosion-resistant (forms protective oxide layer)

- High machinability (easy to cut/drill compared to other metals)

- Thermal/electrical conductivity (ideal for heat sinks, enclosures)

Common Alloys & Uses

AlloyPropertiesTypical Applications

6061 Versatile, weldable Frames, brackets, and automotive parts

7075 High-strength Aerospace, military components

5052 Excellent corrosion resistance, Marine hardware, fuel tanks

2024 Fatigue-resistant Aircraft structures, fasteners

Manufacturing Methods

- CNC Machining: Precision subtractive manufacturing (milling, turning).

- Die Casting: High-volume production of complex shapes.

- Extrusion: Long profiles with consistent cross-sections (e.g., rails, heatsinks).

- Sheet Metal Fabrication: Laser cutting, bending (for enclosures, panels).

Design Tips

- Avoid sharp internal corners (use radii ≥ 1mm).

- Standardize hole sizes to reduce tool changes.

- Specify tolerances only where critical (±0.1mm typical).

1. Introduction to Custom Aluminum Parts

Custom aluminum parts have become a critical component in modern manufacturing. Whether for aerospace, automotive, electronics, robotics, or medical devices, the demand for lightweight, durable, and precision-engineered components has grown exponentially. These parts are engineered to meet exact specifications using advanced techniques, offering flexibility in design, superior corrosion resistance, and excellent thermal and electrical conductivity.

In this comprehensive guide, we’ll explore everything you need to know about custom aluminum parts, from their unique material properties to production methods, industry applications, and supplier selection.

2. Why Aluminum? – Properties and Benefits

Aluminum is the go-to material for custom parts for several key reasons:

-

Lightweight: Aluminum’s density is about one-third that of steel, making it ideal for applications where weight reduction is critical.

-

Corrosion Resistant: Naturally forms a protective oxide layer.

-

Excellent Thermal Conductivity: Ideal for heat dissipation in electronics.

-

Non-Magnetic: Safe for sensitive electronic and medical applications.

-

Highly Machinable: Easier and faster to machine than harder metals.

-

Recyclable: Eco-friendly and cost-effective over time.

These properties make aluminum the perfect candidate for producing precision-engineered custom aluminum parts.

3. Manufacturing Processes for Custom Aluminum Parts

The choice of manufacturing process depends on the complexity, volume, and purpose of the part. Key production methods include:

-

CNC Machining

-

Die Casting

-

Aluminum Extrusion

-

Sheet Metal Fabrication

-

Additive Manufacturing (3D Printing)

Each method has unique advantages in cost, speed, material use, and design flexibility.

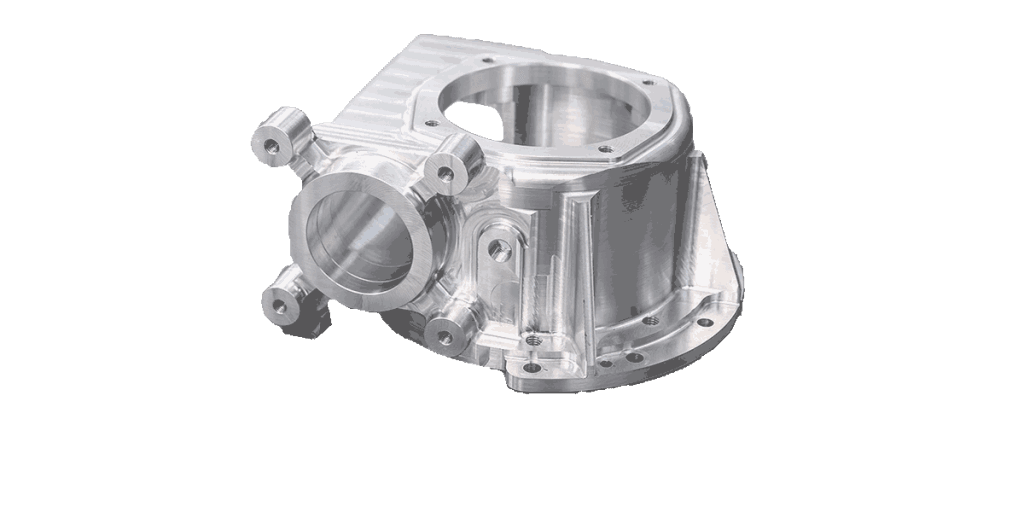

4. CNC Machining for Custom Aluminum Parts

CNC machining is the most popular process for manufacturing custom aluminum parts due to its accuracy and versatility.

Key Features:

-

Multi-axis capabilities (3, 4, 5-axis)

-

Suitable for both prototyping and mass production

-

Tolerances as tight as ±0.01 mm

-

Can produce complex geometries and intricate surface features

CNC machining is especially suitable for aerospace, automotive, robotics, and high-performance consumer products.

5. Die Casting and Aluminum Extrusion

Die Casting:

-

High-volume production

-

Excellent for thin-wall parts

-

Requires upfront mold investment

Aluminum Extrusion:

-

Ideal for linear and complex cross-sectional shapes

-

Efficient for lightweight structural components

Both processes are cost-effective when producing large batches of custom aluminum parts.

6. Surface Finishing Options

Surface finish enhances the appearance, durability, and corrosion resistance of aluminum components. Common finishes include:

-

Anodizing: Provides corrosion resistance and color options

-

Powder Coating: Durable and decorative

-

Bead Blasting: Matte or textured surface

-

Polishing: High-gloss finish

-

Brushing: Uniform, linear texture

Choosing the right finish depends on functional and aesthetic requirements.

7. Design Considerations

Designing custom aluminum parts requires careful consideration of:

-

Wall thickness and geometry

-

Tolerance stack-up

-

Machinability of design features

-

Mounting and assembly interfaces

-

Weight optimization (e.g., pockets or ribs)

Collaborating with experienced engineers can optimize the design for manufacturability and cost-effectiveness.

8. Tolerance and Precision Standards

Different industries require different precision levels. Tolerances often depend on:

-

End-use environment

-

Assembly requirements

-

Load-bearing needs

-

Surface finish and mating part interaction

Aluminum’s machinability allows for excellent dimensional control, critical for high-precision custom aluminum parts.

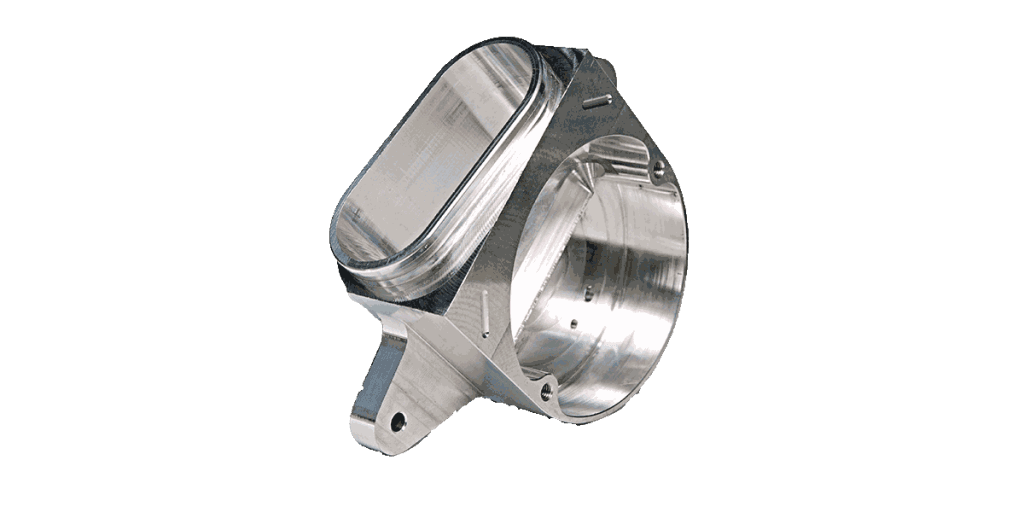

9. Applications Across Industries

Custom aluminum parts are used in virtually every industry. Key examples include:

Aerospace:

-

Lightweight airframe components

-

Instrument housings

Automotive:

-

Engine brackets

-

Transmission housings

Electronics:

-

Heat sinks

-

Enclosures

Medical:

-

Surgical instruments

-

Imaging device housings

Robotics:

-

Custom arm joints

-

Sensor housings

Each application demands specific tolerances, finishes, and certifications.

10. Material Grades for Aluminum Parts

Different aluminum alloys offer varying strengths, corrosion resistance, and thermal properties:

-

6061: General-purpose, excellent machinability and weldability

-

7075: High strength, used in aerospace

-

2024: High fatigue resistance

-

5052: Superior corrosion resistance

-

6063: Excellent for extrusions

Selecting the right alloy ensures optimal performance of custom aluminum parts.

11. Prototyping and Low-Volume Production

Rapid prototyping is essential for product development cycles. CNC machining and 3D printing allow for:

-

Fast iteration

-

Functional testing

-

Market feedback

Custom aluminum prototypes can validate designs before committing to expensive tooling.

12. Mass Production and Quality Control

For large-scale production of custom aluminum parts, rigorous quality control is essential:

-

In-process inspection

-

Coordinate Measuring Machine (CMM)

-

Statistical Process Control (SPC)

-

ISO 9001 or AS9100 certifications

Reliable suppliers provide consistent quality and documentation for traceability.

13. Packaging and Logistics Considerations

Packaging plays a vital role in protecting custom aluminum parts during transit:

-

Anti-scratch wrapping

-

Moisture barriers

-

Custom foam inserts

-

Barcode labeling for inventory management

Logistics planning ensures timely delivery and cost control.

14. Environmental Impact and Recycling

Aluminum is 100% recyclable without losing its properties. Recycled aluminum:

-

Uses only 5% of the energy required to produce new material

-

Reduces CO₂ emissions

-

Aligns with sustainability goals

Choosing recyclable custom aluminum parts benefits both the planet and your bottom line.

15. How to Choose a Custom Aluminum Parts Supplier

When sourcing a supplier, consider:

-

In-house capabilities (machining, finishing, inspection)

-

Certifications and quality standards

-

Lead times and capacity

-

Engineering support

-

Communication and responsiveness

A capable partner ensures the success of your aluminum projects.

16. Common Challenges and Solutions

Warping:

-

Solution: Optimize design and machining strategy

Surface Defects:

-

Solution: Use proper tooling and finishing techniques

Inconsistent Tolerances:

-

Solution: Calibrate machines and follow inspection protocols

Partnering with experts in custom aluminum parts can help mitigate these issues.

17. Future Trends in Aluminum Manufacturing

Looking ahead, advancements in automation, AI, and smart manufacturing will continue to reshape the industry:

-

AI-driven quality inspection

-

Digital twin simulations

-

Hybrid manufacturing techniques

-

Integration of Industry 4.0

These trends will drive faster, smarter, and more sustainable production of custom aluminum parts.

18. Final Thoughts

Custom aluminum parts are vital to modern innovation. Their lightweight, corrosion-resistant nature, combined with advanced production techniques, make them an ideal choice for engineers and designers across industries.

Whether you’re developing the next aerospace marvel or a cutting-edge medical device, partnering with a precision aluminum parts supplier can make the difference between success and failure.

As the demand for quality, speed, and customization increases, understanding the nuances of custom aluminum parts production is more important than ever.