What is the Aluminium Extrusion Process?

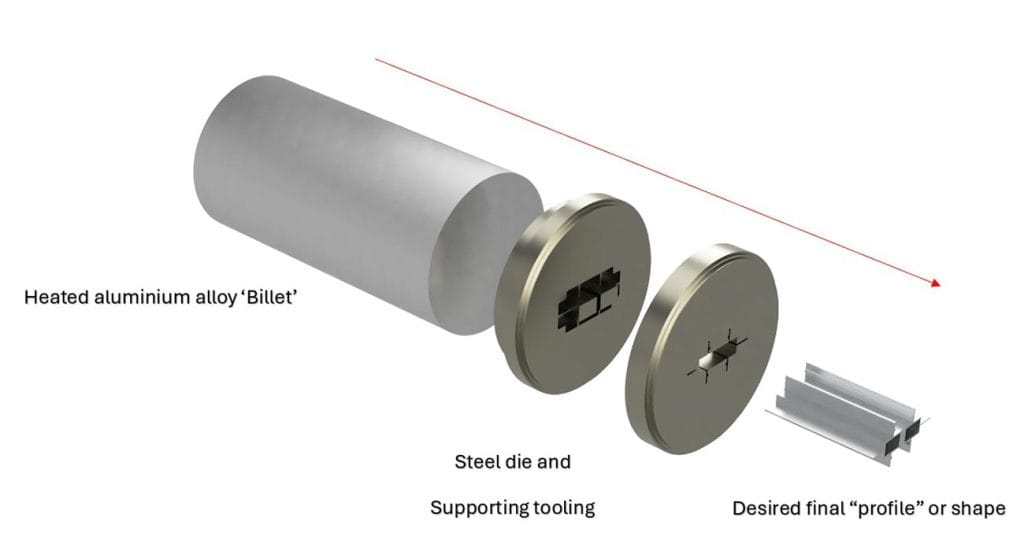

The aluminium extrusion process is a transformative metal-forming technique that converts solid aluminium billets into long, shaped profiles with uniform cross-sections. This is achieved by heating the billet and forcing it through a precision-engineered die using high pressure.

The result is an extruded aluminium shape that can be cut, machined, surface-treated, and assembled into final products. From complex geometries to hollow or semi-hollow forms, the extrusion aluminium process enables unparalleled design freedom while maintaining structural integrity and corrosion resistance.

How Does the Extrusion Aluminium Process Work?

The aluminium extrusion process involves a carefully controlled sequence of steps, each critical to ensuring the accuracy, strength, and surface quality of the final product. Below is a detailed breakdown:

1. Billet Preparation

Aluminium billets are cylindrical solid forms cut from longer logs of raw aluminium alloy. These billets are preheated to a temperature of approximately 400–500°C, making them malleable and suitable for plastic deformation without melting.

2. Extrusion Through a Die

The heated billet is loaded into the chamber of an extrusion press. A hydraulic ram then exerts immense pressure (up to 15,000 tons in large presses), pushing the aluminium through a steel die. The shape of this die determines the final profile, from simple angles and tubes to complex architectural or industrial forms.

There are two primary types of extrusion:

- Direct Extrusion (Forward): The most common method, where the billet and ram move in the same direction.

- Indirect Extrusion (Backward): The die is held stationary, and the billet moves over it — used for more uniform flow and better surface finish.

3. Cooling and Quenching

As the extruded profile exits the die, it is still hot and needs to be cooled rapidly to maintain its shape and metallurgical properties. Depending on the alloy and application, cooling is achieved using air or water spray systems.

4. Stretching and Straightening

After cooling, the extrusions often contain internal stresses or slight bends. They are transferred to a stretcher machine, where they are gently pulled to straighten and align the grain structure. This step ensures dimensional precision.

5. Cutting to Desired Lengths

The extruded profiles are cut into standard lengths, typically 4 to 7 meters, but custom sizing is also possible. Precision cutting ensures easy handling and efficient downstream processing.

6. Heat Treatment (Tempering)

Certain alloys require heat treatment to improve mechanical strength. For example:

- T5: Artificial aging after extrusion

- T6: Solution heat-treated and then aged

This step enhances the profile’s hardness, tensile strength, and fatigue resistance, making the extrusion aluminium process ideal for load-bearing or high-stress applications.

7. Surface Finishing (Optional)

To improve aesthetics, corrosion resistance, or bonding with paint, the extrusions may undergo surface treatment:

- Anodizing: Creates a durable oxide layer for enhanced corrosion resistance.

- Powder Coating: Adds color, texture, and weather resistance.

- Brushing or Polishing: For decorative or visible applications.

1. Introduction to the Aluminium Extrusion Process

The aluminium extrusion process is a thermomechanical manufacturing method in which a heated billet of aluminium alloy is forced through a precision-engineered die, producing a continuous cross-sectional profile. This process is valued for its ability to create lightweight, high-strength components with complex geometries and minimal waste.

Today, the extrusion aluminium process is essential to industries such as transportation, construction, renewable energy, consumer electronics, and aerospace. It supports cost-effective mass production while offering design flexibility unmatched by casting or machining.

2. History and Evolution of Aluminium Extrusion

Aluminium extrusion began in the early 20th century as a niche metal-forming process. Its first major use was in producing wires and tubes for military and electrical applications. With the development of high-strength alloys during World War II and the post-war construction boom, demand for extruded aluminium profiles increased rapidly.

Modern aluminium extrusion leverages sophisticated computer-aided die design, multi-axis presses, and automated quality control systems, allowing for faster cycle times, tighter tolerances, and superior finish quality.

3. Step-by-Step Explanation of the Extrusion Aluminium Process

The aluminium extrusion process involves the following stages:

3.1 Billet Preparation

Raw aluminium logs are cut into billets and preheated to around 400–500°C. This heating softens the material, enabling plastic deformation without liquefaction.

3.2 Extrusion Press Setup

The billet is loaded into the extrusion press container. A hydraulic ram applies pressure (up to 15,000 tons) to push the softened billet through the die opening.

3.3 Profile Formation

As the aluminium flows through the die, it takes on the shape of the die’s cross-section. This profile can be solid, hollow, or semi-hollow depending on the die design.

3.4 Quenching and Cooling

After exiting the die, the hot extruded profile is rapidly cooled using air or water mist to lock in metallurgical properties.

3.5 Stretching

The extruded profile may undergo stretching to remove internal stresses and correct distortions. This ensures straightness and dimensional precision.

3.6 Cutting

Extrusions are cut to length, either into long stock for machining or custom sizes for direct assembly.

3.7 Heat Treatment

Profiles are aged (T5) or solution-treated and artificially aged (T6) to achieve final mechanical properties such as yield strength and hardness.

4. Types of Aluminium Extrusion

There are several extrusion methods, each suitable for different applications:

4.1 Direct Extrusion (Forward Extrusion)

The billet and ram move in the same direction. This is the most common method and supports large-scale production.

4.2 Indirect Extrusion (Backward Extrusion)

The die moves toward the billet while the billet remains stationary. This method reduces friction and improves surface finish.

4.3 Hot vs. Cold Extrusion

While hot extrusion is standard for aluminium, cold extrusion is used for soft metals like lead and tin to improve strength.

5. Common Aluminium Alloys for Extrusion

Alloy selection depends on strength, corrosion resistance, machinability, and finish requirements. Common choices:

- 6061: General-purpose alloy used in structural and transport components.

- 6063: Architectural alloy with excellent surface finish.

- 6082: Stronger alternative to 6061; ideal for load-bearing parts.

- 7075: High-strength aerospace-grade alloy.

- 2024: Excellent fatigue resistance; used in aircraft fuselage components.

Each alloy behaves differently during the extrusion aluminium process, requiring optimized temperature control and extrusion speed.

6. Design and Manufacturing

Dies are typically made of hardened tool steel and designed using CAD/CAM software. Types include:

- Solid dies: Produce simple, closed shapes (rods, bars).

- Hollow dies: For tubing, channels, and multi-void profiles.

- Bridge or porthole dies: Enable extrusion of complex hollow forms.

Life is extended through surface nitriding and regular polishing.

7. Equipment Used in Aluminium Extrusion

Key equipment includes:

- Extrusion Press: Rated from 600 to 10,000 tons of force.

- Billet Heater: Electric or gas induction units for precise temperature control.

- Die Oven: Maintains die at operating temperature (~450°C).

- Pullers & Stretchers: Ensure dimensional consistency.

- Cooling Tables & Quenching Systems: Control thermal gradients.

- Automated Cut-off Saws: For consistent length and edge quality.

Modern plants are integrated with real-time data acquisition systems for monitoring and process optimization.

8. Surface Treatments and Finishing Options

Aluminium extrusions are often finished to enhance corrosion resistance, appearance, or performance:

- Anodizing: Adds a durable, decorative oxide layer (colorable).

- Powder Coating: For UV and chemical resistance with aesthetic appeal.

- Mechanical Finishes: Brushing, sandblasting, polishing.

- Chemical Conversion Coating: Primer for better paint adhesion.

9. Quality Control and Tolerance Management

Precision is critical in the aluminium extrusion process. Key quality metrics include:

- Dimensional tolerances per EN 755 or ASTM B221 standards.

- Mechanical properties (yield strength, elongation, hardness).

- Surface finish (roughness, gloss, adhesion).

- Microstructure analysis (grain size, voids, inclusions).

Quality assurance uses tools like CMM, spectrometers, and X-ray flaw detection.

10. Industrial Applications of the Extrusion Aluminium Process

The extrusion aluminium process supports a wide array of high-performance sectors:

10.1 Automotive & EV

- Battery trays

- Bumpers

- Roof rails

- Crash management systems

10.2 Aerospace

- Seat rails

- Cabin supports

- Wing stiffeners

10.3 Architecture & Construction

- Curtain wall frames

- Modular facades

- Railing systems

10.4 Electronics & Thermal Management

- Heat sinks

- Enclosures

- LED housings

10.5 Renewable Energy

- Solar panel frames

- Wind turbine structures

- Mounting brackets

11. Sustainability and Recycling in Aluminium Extrusion

Aluminium is infinitely recyclable, with 95% energy savings compared to primary production. Many extrusion plants:

- Use recycled billets (secondary aluminium).

- Implement closed-loop cooling systems.

- Operate with low-carbon energy sources.

- Reduce scrap through lean manufacturing.

Green certifications such as ISO 14001 and ASI (Aluminium Stewardship Initiative) ensure environmental compliance.

12. Advantages and Limitations of the Process

Advantages

- Exceptional design flexibility

- Lightweight yet strong

- High productivity and repeatability

- Excellent surface finishes

- Environmentally sustainable

Limitations

- Die costs for custom profiles

- Limited wall thickness for complex hollows

- Strength is lower than forged parts in critical areas

- Requires post-processing for certain tolerances

13. Frequently Asked Questions (FAQ)

Q1: How long does aluminium extrusion take?

A: Cycle times range from seconds to minutes depending on profile complexity, length, and alloy.

Q2: Is aluminium extrusion expensive?

A: Tooling costs are higher than casting, but the long-term cost per part is low due to repeatability.

Q3: Can aluminium extrusions be welded?

A: Yes, especially 6xxx series alloys. TIG and MIG welding are commonly used.

Q4: What’s the thinnest wall that can be extruded?

A: With proper die design, wall thickness as low as 0.5 mm can be achieved.

Q5: Can you extrude aluminum with embedded features?

A: Yes — knurls, channels, screw ports, and even snap-fit elements are feasible.

14. Choosing the Right Aluminium Extrusion Partner

Look for suppliers with:

- In-house die design and CNC capabilities

- Alloy certification and traceability

- ISO 9001, IATF 16949, or AS9100 accreditation

- Strong engineering support

- Proven case studies in your sector

Working with a reliable manufacturer ensures optimal results, lower rework, and faster time-to-market.

15. Conclusion

The aluminium extrusion process stands at the core of precision metal forming, offering unmatched flexibility, strength, and scalability. With its ability to create high-performance, sustainable, and visually appealing products, the extrusion aluminium process continues to power progress across nearly every modern industry.

Whether you’re designing components for the aerospace sector, EV manufacturing, or architectural innovation, aluminium extrusion offers the tools to turn bold ideas into a reliable reality.

Ready to start your project?

👉 Contact us today for expert consultation, rapid prototyping, or a custom extrusion solution tailored to your exact specifications.